BGA Voids and Their Sources in SMT Assemblies

Ball grid array (BGA) is widely used because of its inherent advantage in producing overall lower defects. However, one defect that has been of greatest interest to the industry has been voids. The IPC 7095 “Design and Assembly Process Implementation for BGA” committee has made significant changes in accept/reject criteria of voids. The revised version — IPC-7095 A — soon will be released with extensive changes in all aspects of BGA design and assembly. My next columns will highlight the changes in void acceptance as specified in IPC 7095. As the chairman of this committee, I welcome your comments and input.

IPC 7095 is a detailed document and the final decision about accept/reject criteria was made by taking into account two things: available industry data on the impact of voids on reliability, and using common sense as to what is reasonable if using recommended BGA design and assembly processes.

Voids are not unique to BGAs, and can be detected under leaded components when using X-ray equipment. However, leaded component solder joints historically have been inspected visually, not X-rayed, and therefore never detected.

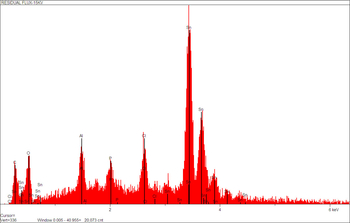

Although current industry data suggests that solder joint voids are not a reliability concern, the presence of voids indicates that manufacturing parameters may need to be adjusted. Two reported causes of voids are trapped flux that has not had enough time to be released from the solder paste, and contaminants on improperly cleaned circuit boards. Voids appear as a lighter area inside the solder balls and typically are found randomly throughout the package. X-ray systems tend to distort the size of voids due to blooming. It is possible to accurately measure the true volume of a void; however, the procedure can be involved and requires a known reference for radiometric calibration of the X-ray film or detector. In most cases, the effort is better spent on identifying and eliminating the cause of the voids by using commonly known design and assembly materials and process parameters.

Sources of Voids

Voids can be found in a BGA solder ball, in the solder joint to BGA interface or in the solder joint to printed circuit board (PCB) interface. Various factors are responsible for these voids. Voids can be carried over from original voids in solder balls, which could be the result of the ball manufacturing process. Voids also can be induced into the reflowed solder joint by either the voids in the original component solder ball or during the reflow attachment process. Additionally, voids can form near the PCB to ball interface during BGA to PCB attachment.

These voids typically are formed during the reflow soldering process by flux volatiles trapped during the solidification of the molten solder. The source of flux volatiles either can be from applied flux itself (typically rework) or flux that is one of the constituents of the solder paste used in the reflow assembly process. Voids also can be formed by air expanding from plugged vias (via-in-pad consideration) in the PCB. Expanding air from a plugged via under a land also may create a void.

Generally, most voids are detected in the middle to top (ball/BGA interface) of the reflowed solder joint. This is expected because the trapped air bubble and the vaporized flux, which is applied to the PCB BGA lands, rise during the reflow profile. This occurs when the applied solder paste and the BGA’s collapsible eutectic solder ball(s) melt together during the reflow profile (typically 210º to 230ºC peak temperature). If the reflow profile cycle does not allow sufficient time for either the trapped air or vaporized flux to escape, a void is formed as the molten solder solidifies in the cool down area of the reflow profile. Therefore, reflow profile development is important as a contributor to void formation.

BGA components having noncollapsible balls (high-temperature solder 90 percent Pb/10 percent Sn, with a melting point of 302ºC) typically will have few or no induced voids because the ball solder never melts during the reflow profile.

Voids also are impacted by use of lead-free solder balls or paste. For example, if 63Sn/37Pb BGA balls are soldered with lead-free solder paste, void incidence may be high. This scenario, commonly referred to as Forward Compatibility, is not theoretical but very real in the transition phase to lead-free in which the assembly house has converted to lead-free but the components are not available yet in lead-free. Because eutectic solder balls with lower temperatures of about 50ºC will melt much sooner than the high-temperature lead-free solder paste, multiple volatiles from the solder paste will end up getting trapped in the balls during the cooling phase.

In the case of Backward Compatibility (the components are lead-free but the assembly house is still using 63Sn/37Pb), voiding is not an issue since the ball would melt much later than the solder paste. Other problems with backward compatibility include diffusion of lead in the grain boundaries, raising solder joint reliability concern. This problem can be alleviated by raising the reflow temperature above the melting point of lead-free balls.

It is critical that the process be qualified for void acceptance before being released for production regardless of the type of paste or balls used.

Void Impact

How many and what size voids should be allowed in the product before they impact the product’s required reliability? Voids may impact reliability by weakening the solder balls and reducing functionality because the reduced cross-section will have lower heat transfer than current carrying capabilities. Large voids are more detrimental but small pre-existing voids can merge during reflow to create large voids.

Eliminating voids, or at least reducing them substantially, is preferred. Numerous studies show that a small reliability increase is a result of moderate-size voids. These typically are from processes that are in control. Increased reliability results from increased solder joint height as well as a temporary and local retardation of crack propagation.

Unlike a leaded component, BGAs have solder joints that are not only on the component’s periphery, but have internal solder joints that are not inspectable by normal visual techniques. X-ray equipment is required for void inspection or detection in BGA solder joints.

Ray P. Prasad is an SMT Editorial Advisory Board member and author of the textbook Surface Mount Technology: Principles and Practice. Additionally, he is president of BeamWorks Inc. and founder of the Ray Prasad Consultancy Group. Contact him at www.rayprasad.com.

IPC 7095 is a detailed document and the final decision about accept/reject criteria was made by taking into account two things: available industry data on the impact of voids on reliability, and using common sense as to what is reasonable if using recommended BGA design and assembly processes.

Voids are not unique to BGAs, and can be detected under leaded components when using X-ray equipment. However, leaded component solder joints historically have been inspected visually, not X-rayed, and therefore never detected.

Although current industry data suggests that solder joint voids are not a reliability concern, the presence of voids indicates that manufacturing parameters may need to be adjusted. Two reported causes of voids are trapped flux that has not had enough time to be released from the solder paste, and contaminants on improperly cleaned circuit boards. Voids appear as a lighter area inside the solder balls and typically are found randomly throughout the package. X-ray systems tend to distort the size of voids due to blooming. It is possible to accurately measure the true volume of a void; however, the procedure can be involved and requires a known reference for radiometric calibration of the X-ray film or detector. In most cases, the effort is better spent on identifying and eliminating the cause of the voids by using commonly known design and assembly materials and process parameters.

Sources of Voids

Voids can be found in a BGA solder ball, in the solder joint to BGA interface or in the solder joint to printed circuit board (PCB) interface. Various factors are responsible for these voids. Voids can be carried over from original voids in solder balls, which could be the result of the ball manufacturing process. Voids also can be induced into the reflowed solder joint by either the voids in the original component solder ball or during the reflow attachment process. Additionally, voids can form near the PCB to ball interface during BGA to PCB attachment.

These voids typically are formed during the reflow soldering process by flux volatiles trapped during the solidification of the molten solder. The source of flux volatiles either can be from applied flux itself (typically rework) or flux that is one of the constituents of the solder paste used in the reflow assembly process. Voids also can be formed by air expanding from plugged vias (via-in-pad consideration) in the PCB. Expanding air from a plugged via under a land also may create a void.

Generally, most voids are detected in the middle to top (ball/BGA interface) of the reflowed solder joint. This is expected because the trapped air bubble and the vaporized flux, which is applied to the PCB BGA lands, rise during the reflow profile. This occurs when the applied solder paste and the BGA’s collapsible eutectic solder ball(s) melt together during the reflow profile (typically 210º to 230ºC peak temperature). If the reflow profile cycle does not allow sufficient time for either the trapped air or vaporized flux to escape, a void is formed as the molten solder solidifies in the cool down area of the reflow profile. Therefore, reflow profile development is important as a contributor to void formation.

BGA components having noncollapsible balls (high-temperature solder 90 percent Pb/10 percent Sn, with a melting point of 302ºC) typically will have few or no induced voids because the ball solder never melts during the reflow profile.

Voids also are impacted by use of lead-free solder balls or paste. For example, if 63Sn/37Pb BGA balls are soldered with lead-free solder paste, void incidence may be high. This scenario, commonly referred to as Forward Compatibility, is not theoretical but very real in the transition phase to lead-free in which the assembly house has converted to lead-free but the components are not available yet in lead-free. Because eutectic solder balls with lower temperatures of about 50ºC will melt much sooner than the high-temperature lead-free solder paste, multiple volatiles from the solder paste will end up getting trapped in the balls during the cooling phase.

In the case of Backward Compatibility (the components are lead-free but the assembly house is still using 63Sn/37Pb), voiding is not an issue since the ball would melt much later than the solder paste. Other problems with backward compatibility include diffusion of lead in the grain boundaries, raising solder joint reliability concern. This problem can be alleviated by raising the reflow temperature above the melting point of lead-free balls.

It is critical that the process be qualified for void acceptance before being released for production regardless of the type of paste or balls used.

Void Impact

How many and what size voids should be allowed in the product before they impact the product’s required reliability? Voids may impact reliability by weakening the solder balls and reducing functionality because the reduced cross-section will have lower heat transfer than current carrying capabilities. Large voids are more detrimental but small pre-existing voids can merge during reflow to create large voids.

Eliminating voids, or at least reducing them substantially, is preferred. Numerous studies show that a small reliability increase is a result of moderate-size voids. These typically are from processes that are in control. Increased reliability results from increased solder joint height as well as a temporary and local retardation of crack propagation.

Unlike a leaded component, BGAs have solder joints that are not only on the component’s periphery, but have internal solder joints that are not inspectable by normal visual techniques. X-ray equipment is required for void inspection or detection in BGA solder joints.

Ray P. Prasad is an SMT Editorial Advisory Board member and author of the textbook Surface Mount Technology: Principles and Practice. Additionally, he is president of BeamWorks Inc. and founder of the Ray Prasad Consultancy Group. Contact him at www.rayprasad.com.

Registration is Open for SMT Course

Registration is Open for SMT Course

Ray Prasad will be teaching his flagship SMT course: