SMT- How clean is clean? Well, make up something.

There is no other requirement as confusing and muddled in our industry as the definition of cleanliness of an electronics assembly board. And the industry document such as J-STD-001D that most people look to is currently out for ballot simply adds to the confusion.

But before I go into the details let me first cover some basics about fluxes and what they do and why we need to clean or not clean. There are four types of fluxes: Rosin (RO), Resin (RE), and Organic (OR) and inorganic (IN). Each flux type has three different activity levels to choose from (low, medium and high). These three levels L, M and H come with or without halides. So when do you the math there are total of 24 different flux categories to choose from -- a daunting task indeed. Fluxes with no halides have 0 and fluxes with halides have 1 at the end of their designations. For example, rosin flux without halide will be called ROL0 and rosin flux with halide will be called ROL1.

These designations repeat for RE, OR and IN as well, thus making up 24 categories of fluxes. Halides in L1, M1 and H1 are less than 0.5%, 0.5 to 2% and more than 2% respectively. The activity in the halide free fluxes comes from naturally occurring acids. The higher the flux activity, the better the soldering results. However, more active fluxes must be cleaned properly to prevent corrosion in the field. No clean fluxes can be RO or RE with or without halides. But OR fluxes must be without halides (ORL0) to be classified as no clean. Due to very high activity levels, Inorganic (IN) fluxes commonly used by your plumber are not used in the electronics industry.

The reason we need flux is to deoxidize the metallic surfaces to be soldered, otherwise intermetallic bonding will not take place. However, any corrosive material left on the surface must be cleaned after soldering. In less active fluxes, the chemicals such as carboxylic acids, activate and perform their deoxidizing function, then burn off and no active chemicals are left on the surface to cause any corrosion and hence shorting of circuits in the field. When using more active fluxes, it is imperative that cleaning be done with appropriate solvents to remove any contaminants that can cause field failures due to dendritic growth and corrosion. But how do you know you have got it clean enough not to cause any problem in the field? If you asked a similar question about solder joint causing any reliability problem in the field, in all kinds of unknown environments, it would be very easy to answer since there are accept/reject criteria in J-STD-001 and shown in color photos in IPC-610.

But if you want to know how clean a board is, J-STD-001C (currently in effect) has guideline for cleanliness of 1.56 microgram/square centimeter of NaCl equivalent (or 10.06 microgram/square inch) using solvent extract test methods. But the new version -- J-STD-001D, currently out for ballot, establishes the cleanliness requirement only for rosin fluxes with and without halides (R0 and R1 varieties). But if you are a user of resin (RE) and organic (OR) fluxes as a great majority of you are, and if you want to know the cleanliness requirement for your boards, you are on your own. The cleanliness requirements for RE and OR fluxes has been left to the users and suppliers to decide without any industry guidance. The argument can be made that the

J-STD-001 committee has no way to know the end use requirements and compatibility or rather incompatibility of different materials such as flux, solvents, solder mask and conformal coating.

While I agree that it is a hard task, the reality is that you never have all the data that you need to make a decision. We have established all kinds of requirements for board, materials, solder joints. Are they all based on data? Some of it are but the rest is based on some good common sense and good industry practices assuming you know what you are doing.

What will be the implications of this lack of industry guidelines on board cleanliness? There will be those who will think that if you use no clean flux or paste, there is nothing to worry about and you should not even bother about checking board cleanliness. People will make up their own requirements. Here are some examples. In one case a supplier would not even agree to 10.06 microgram/sq inch of NaCl even though he was having as much as 90 micrograms/per sq inch contaminants and extensive white residues on some of his board at times. And the exact same flux used on the same product at another factory was getting well below 10. Here is another example. People are even specifying not only arbitrary requirements using this yet unpublished document but even specifying what flux to use to achieve those numbers and get it validated by extensive (and expensive) lab tests. This is really good news for test labs.

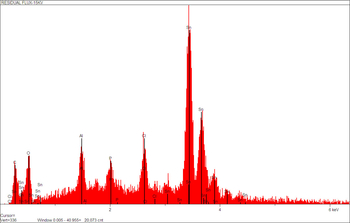

So with a lack of industry guidance, different companies will be inventing their own test methods and requirements such as ion chromatography or IC test and sometimes the acceptance requirements can be arbitrary based on some confidential data not publicly available such as 2.5 microgram of NaCl equivalent/square inch as measured by IC when using no clean and much higher number (4.5 microgram) when using more aggressive water soluble fluxes.

I donít quite see the reason for using much higher IC number when using more aggressive fluxes especially when you use fine pitch devices with practically no stand off. Any flux trapped under the fine pitch devices of almost zero stand-off will not come out no matter how long you clean and they cannot be found by IC test or solvent extract test.

You can see the problem here due to lack of clear industry guidance. Of course users and suppliers can develop their own specs for cleanliness acceptance but in absence of an industry guideline, everyone is clueless as to how clean is clean. Here are some of my thoughts. I would love to hear your comments.

Today a lot of people would argue that Solvent Extract is relevant only for rosin. And that must have been the reason for making the change in the current revision of J-STD-001D out for ballot. But what have we been doing for the last few decades? You guessed it. Solvent extract and I am talking about this test being used for all kinds of fluxes and all kinds of applications.

In addition to solvent extract, another test method that has been used extensively is SIR (surface insulation resistance). Actually in my Intel days when we were using aggressive water soluble fluxes, SIR value of 500 Megohm/square (yes, per square and not per sq inch) on production board under chip components, on a sampling basis, was the acceptance criteria. This test helped us discover many problems such as poor adhesive cure profile that was trapping flux due to voids in the adhesive and making sure we donít ship any product with corrosion potential in the field. And the same was the case at Boeing where we used solvent extract when using aggressive water soluble fluxes for military aircrafts. Those airplanes are still flying and those computers are still working. So you cannot say solvent extract has been a bad test method.

The argument for not specifying a cleanliness requirement for RE and OR fluxes is that you cannot possibly develop an acceptance criteria with repeatable test methods when you donít really know what kinds of substrates, solder masks and coatings these fluxes will interact with in some unknown environment. This argument may be valid but we can ask the same question when it comes to RO fluxes. Besides, this problem can be solved by reasonable people by being little conservative to accommodate RE and OR fluxes in a very humid environment as we have done for R0 fluxes. We can make an exception for applications where you are sending a manned mission to Mars and you can afford to do all kinds of tests in the book if you are using RE and OR fluxes. But we are not all sending the assemblies to manned mission on Mars.

Besides, if you are going to have a corrosion problem, does it really matter which kind of flux it came from? For example, you can have a corrosion problem even from rosin flux if you use them generously for rework leaving behind lots of flux that never got hot enough to be activated to become benign.

There are three simple requirements that should be given the force of an industry standard such as J-STD-001 or any other IPC standard for that matter. First there should be no visible flux residue except for some no clean flux residue (and I must thank the J-STD-001 for making it clear) but there should be no white or corroded look appearance no matter what kind of flux residue is on the board.

Second, since solvent extract is commonly used, the 10.06 microgram per square inch that has served the industry for so long should be used for all fluxes. However, if users and suppliers agree, they can use some other test such as ion chromatography (IC) or any other mutually acceptable tests and the level of NaCl equivalent number from 2.5 to 4.5 microgram/square inch being used by some companies for IC.

And finally, the most important criteria, at least to qualify the flux before use, the surface insulation resistance value taken in humidity chamber at 100 volt dc should be 500 megohm/square to detect any trapped flux under components with practically no stand off.

There is hope. The good news is that IPC has four Task Groups in the 5-32 Cleanliness Assessment Subcommittee whose function it is to establish cleanliness requirements -- how to do cleanliness testing and how to measure the results and what cleanliness might be required for end use environment. May be they will come up with something soon enough. Let us hope so. And to help them expedite their work, at least the major OEMs and subcontractors should invest some R&D dollars to help develop a clear industry guideline on this important subject.

In the mean time, how clean is clean? Well, you can see some of my suggestions in this column. Or make up something, at least for now.

These are some of my thoughts. You can contact IPC by e-mail to: answers@ipc.org to express your thoughts.

But before I go into the details let me first cover some basics about fluxes and what they do and why we need to clean or not clean. There are four types of fluxes: Rosin (RO), Resin (RE), and Organic (OR) and inorganic (IN). Each flux type has three different activity levels to choose from (low, medium and high). These three levels L, M and H come with or without halides. So when do you the math there are total of 24 different flux categories to choose from -- a daunting task indeed. Fluxes with no halides have 0 and fluxes with halides have 1 at the end of their designations. For example, rosin flux without halide will be called ROL0 and rosin flux with halide will be called ROL1.

These designations repeat for RE, OR and IN as well, thus making up 24 categories of fluxes. Halides in L1, M1 and H1 are less than 0.5%, 0.5 to 2% and more than 2% respectively. The activity in the halide free fluxes comes from naturally occurring acids. The higher the flux activity, the better the soldering results. However, more active fluxes must be cleaned properly to prevent corrosion in the field. No clean fluxes can be RO or RE with or without halides. But OR fluxes must be without halides (ORL0) to be classified as no clean. Due to very high activity levels, Inorganic (IN) fluxes commonly used by your plumber are not used in the electronics industry.

The reason we need flux is to deoxidize the metallic surfaces to be soldered, otherwise intermetallic bonding will not take place. However, any corrosive material left on the surface must be cleaned after soldering. In less active fluxes, the chemicals such as carboxylic acids, activate and perform their deoxidizing function, then burn off and no active chemicals are left on the surface to cause any corrosion and hence shorting of circuits in the field. When using more active fluxes, it is imperative that cleaning be done with appropriate solvents to remove any contaminants that can cause field failures due to dendritic growth and corrosion. But how do you know you have got it clean enough not to cause any problem in the field? If you asked a similar question about solder joint causing any reliability problem in the field, in all kinds of unknown environments, it would be very easy to answer since there are accept/reject criteria in J-STD-001 and shown in color photos in IPC-610.

But if you want to know how clean a board is, J-STD-001C (currently in effect) has guideline for cleanliness of 1.56 microgram/square centimeter of NaCl equivalent (or 10.06 microgram/square inch) using solvent extract test methods. But the new version -- J-STD-001D, currently out for ballot, establishes the cleanliness requirement only for rosin fluxes with and without halides (R0 and R1 varieties). But if you are a user of resin (RE) and organic (OR) fluxes as a great majority of you are, and if you want to know the cleanliness requirement for your boards, you are on your own. The cleanliness requirements for RE and OR fluxes has been left to the users and suppliers to decide without any industry guidance. The argument can be made that the

J-STD-001 committee has no way to know the end use requirements and compatibility or rather incompatibility of different materials such as flux, solvents, solder mask and conformal coating.

While I agree that it is a hard task, the reality is that you never have all the data that you need to make a decision. We have established all kinds of requirements for board, materials, solder joints. Are they all based on data? Some of it are but the rest is based on some good common sense and good industry practices assuming you know what you are doing.

What will be the implications of this lack of industry guidelines on board cleanliness? There will be those who will think that if you use no clean flux or paste, there is nothing to worry about and you should not even bother about checking board cleanliness. People will make up their own requirements. Here are some examples. In one case a supplier would not even agree to 10.06 microgram/sq inch of NaCl even though he was having as much as 90 micrograms/per sq inch contaminants and extensive white residues on some of his board at times. And the exact same flux used on the same product at another factory was getting well below 10. Here is another example. People are even specifying not only arbitrary requirements using this yet unpublished document but even specifying what flux to use to achieve those numbers and get it validated by extensive (and expensive) lab tests. This is really good news for test labs.

So with a lack of industry guidance, different companies will be inventing their own test methods and requirements such as ion chromatography or IC test and sometimes the acceptance requirements can be arbitrary based on some confidential data not publicly available such as 2.5 microgram of NaCl equivalent/square inch as measured by IC when using no clean and much higher number (4.5 microgram) when using more aggressive water soluble fluxes.

I donít quite see the reason for using much higher IC number when using more aggressive fluxes especially when you use fine pitch devices with practically no stand off. Any flux trapped under the fine pitch devices of almost zero stand-off will not come out no matter how long you clean and they cannot be found by IC test or solvent extract test.

You can see the problem here due to lack of clear industry guidance. Of course users and suppliers can develop their own specs for cleanliness acceptance but in absence of an industry guideline, everyone is clueless as to how clean is clean. Here are some of my thoughts. I would love to hear your comments.

Today a lot of people would argue that Solvent Extract is relevant only for rosin. And that must have been the reason for making the change in the current revision of J-STD-001D out for ballot. But what have we been doing for the last few decades? You guessed it. Solvent extract and I am talking about this test being used for all kinds of fluxes and all kinds of applications.

In addition to solvent extract, another test method that has been used extensively is SIR (surface insulation resistance). Actually in my Intel days when we were using aggressive water soluble fluxes, SIR value of 500 Megohm/square (yes, per square and not per sq inch) on production board under chip components, on a sampling basis, was the acceptance criteria. This test helped us discover many problems such as poor adhesive cure profile that was trapping flux due to voids in the adhesive and making sure we donít ship any product with corrosion potential in the field. And the same was the case at Boeing where we used solvent extract when using aggressive water soluble fluxes for military aircrafts. Those airplanes are still flying and those computers are still working. So you cannot say solvent extract has been a bad test method.

The argument for not specifying a cleanliness requirement for RE and OR fluxes is that you cannot possibly develop an acceptance criteria with repeatable test methods when you donít really know what kinds of substrates, solder masks and coatings these fluxes will interact with in some unknown environment. This argument may be valid but we can ask the same question when it comes to RO fluxes. Besides, this problem can be solved by reasonable people by being little conservative to accommodate RE and OR fluxes in a very humid environment as we have done for R0 fluxes. We can make an exception for applications where you are sending a manned mission to Mars and you can afford to do all kinds of tests in the book if you are using RE and OR fluxes. But we are not all sending the assemblies to manned mission on Mars.

Besides, if you are going to have a corrosion problem, does it really matter which kind of flux it came from? For example, you can have a corrosion problem even from rosin flux if you use them generously for rework leaving behind lots of flux that never got hot enough to be activated to become benign.

There are three simple requirements that should be given the force of an industry standard such as J-STD-001 or any other IPC standard for that matter. First there should be no visible flux residue except for some no clean flux residue (and I must thank the J-STD-001 for making it clear) but there should be no white or corroded look appearance no matter what kind of flux residue is on the board.

Second, since solvent extract is commonly used, the 10.06 microgram per square inch that has served the industry for so long should be used for all fluxes. However, if users and suppliers agree, they can use some other test such as ion chromatography (IC) or any other mutually acceptable tests and the level of NaCl equivalent number from 2.5 to 4.5 microgram/square inch being used by some companies for IC.

And finally, the most important criteria, at least to qualify the flux before use, the surface insulation resistance value taken in humidity chamber at 100 volt dc should be 500 megohm/square to detect any trapped flux under components with practically no stand off.

There is hope. The good news is that IPC has four Task Groups in the 5-32 Cleanliness Assessment Subcommittee whose function it is to establish cleanliness requirements -- how to do cleanliness testing and how to measure the results and what cleanliness might be required for end use environment. May be they will come up with something soon enough. Let us hope so. And to help them expedite their work, at least the major OEMs and subcontractors should invest some R&D dollars to help develop a clear industry guideline on this important subject.

In the mean time, how clean is clean? Well, you can see some of my suggestions in this column. Or make up something, at least for now.

These are some of my thoughts. You can contact IPC by e-mail to: answers@ipc.org to express your thoughts.

Registration is Open for SMT Course

Registration is Open for SMT Course

Ray Prasad will be teaching his flagship SMT course: