SMT - Mass Rework? Automated? You must be Kidding!

Mass rework? Automated? Why would anyone need to do mass rework? Are they totally new to SMT? Haven’t companies figured out ways to control their process? After all, the technology has been in very high-volume use since the mid-1980s. Do we still need to do rework?

In an ideal world there would be no rework. Welcome to the real world. We have been doing through-hole assembly since the mid-1950s. We don’t have zero-defect in through-hole assemblies yet. We will never have zero-defect in any assembly — through-hole or SMT — as long as we need humans to do things.

Whatever the reasons, less than 10 percent of companies have first pass yields of more than 90 percent. To put it differently, 90 percent of companies perform excessive rework. What are the reasons for such poor performance? There are three major causes of defects: design for manufacturing (DFM), quality of incoming materials (i.e., adhesive, solder paste, boards and components) and in-house SMT infrastructure (i.e., equipment set up, thermal profile, documentation and training) at all levels in the organization. Training is very important. Nobody gets up in the morning and says, “I am going to screw up three things at work today.”

With the major trend toward outsourcing today, the contract manufacturer (CM) controls less than two thirds of defect causes because, in most cases, the OEM designs the board and is responsible for DFM. Typically even then, the OEM tells the CM who his suppliers are for the component and boards. If the CM is working on a consignment basis, in which all parts and boards are supplied by the OEM, he has control only over one third of the causes of defects. So while the CM generally has no or very little control over DFM and the quality of incoming material, he bears 100 percent responsibility (blame, actually) for the defects. I think we all can agree that rework is never going to go away. We can minimize it but we cannot eliminate it. It is important to reconcile with this reality so that resources can be put in place to address it. Most people probably agree that we have to deal with rework. But mass rework? That is another matter entirely.

Why Mass Rework?

I have been in the SMT industry for some time. I have yet to visit a company where mass rework has not been needed. The fortunate thing is that it happens only occasionally. When it does happen, however, it is a major crisis. For example, say 36 components (same component) have to be replaced on each board and you have to rework 5,000 boards. How and why do such things happen? Very simply, it could be that a wrong reel with a different part number was placed with the same types and number of leads. But what is the excuse for building such large quantity assemblies?

One reason the SMT process is so pervasive is that it is very high-speed and, hence, is natural for automation. But also keep in mind that if anything, no matter how trivial, goes wrong it takes almost no time to build thousands of assemblies that must be scrapped before the problem is discovered. If this has not happened to you, you are in denial, extremely lucky or have achieved nirvana.

If you do deal with high-volume rework, you are in big trouble with existing technology because it takes from 12 to 60 minutes to remove and replace one component. That is only one to five components per hour. For 100,000 components, assuming 12 minutes per component, that is 10 years! This is when you need an automated rework system.

Integrating Automated Inspection and Rework

In the May 2001 issue, there is an article by Fred Schlieper1 discussing benefits of integrating inspection and rework. While this article focuses on integrating X-ray and rework systems, the concept is equally valid for integrating automated optical inspection (AOI) with automated rework systems. The inspection system finds the problems and the rework system fixes them automatically. This creates an interesting opportunity for both the suppliers of these machines and the end customer. With the integrated system, problems are fixed with gathered data and corrective action is implemented to prevent future repetition.

There is one minor problem with automated rework systems. Does such a system exist? Before I answer this question, let us agree on the definition of automated rework systems.

In a fully automated rework system, all rework process steps — defective part removal, solder paste or flux application, vision-assisted precision placement of small and large components from tape-and-reel feeders or trays, and reflow without overheating the part being removed or reflowing neighboring components — must be accomplished automatically, without human intervention. And it also is helpful if the board does not warp because of intense local heating. A tall order, indeed. Does such a system exit?

Automated Rework Systems

There are many rework systems on the market today. They vary in cost from a few hundred dollars to $160,000. These systems are either manual or semiautomated. When I say semiautomated, I basically mean component placement either is totally manual or the operator gets some help in aligning the part for placement. And solder paste dispensing or printing is done manually with a syringe or ministencil. A ministencil is needed for each part type.

To fully automate rework, not a single machine but an assembly system that can selectively dispense solder paste, place components and reflow components without heating neighboring components is needed. The system also needs to be fairly fast to assemble quickly and automatically to meet the mass rework requirements. To provide a real relief, it must be able to selectively assemble many part types without the problem (and the cost that can add up quickly) of changing nozzles and stencils for each part type. There is only one system on the market (at least for now) that can perform all the functions of rework — Spark 400R from BeamWorks.

Before I briefly describe this machine, let me make a public disclosure to avoid any conflict of interest. I have significant interest in BeamWorks. I have been working with BeamWorks since its inception about three years ago and currently I play a major role in its operation. I also am an investor in this company.

Spark 400R from BeamWorks is as an automated rework system. It performs all the functions of a rework operation — component removal, solder paste dispensing, component placement and laser soldering. Soldering and inspection functions are performed concurrently to provide real-time feedback on solder joint quality. It tailors heat input not only to a specific component but also to a specific lead. In other words, if a certain lead of a given component is connected to power or ground plane, the laser soldering time is longer for that lead than the adjacent lead that is not connected to any heat sink. Think of it as an assembly system that uses a unique solder profile not for a board but rather an individual lead.

Because the machine dispenses paste (or flux as is generally the case because enough solder is left on the pad after component removal), there is no need to spend money on ministencils for each component. Paste or flux dispensing, as the case may be, is done either as dots or a thin strip of paste or flux. Then, using the same computer-aided design (CAD) data, the system places components and solders them using four diode lasers. An important benefit is that the laser does not reflow solder joints of adjacent components even if they are only 0.020" away and does not need any nozzles. Because the board is not heated (only the solder pads are), board warpage is a non-issue. Also, because the heat source for reflow is a diode laser, the moisture-sensitive components already assembled (or to be assembled) do not require baking. This is very important when you want to selectively assemble only certain components.

Having such a system makes rework not the dreaded operation it is thought to be. Because all operations are performed without human intervention, quality is consistent. Because reflow time is in milliseconds as opposed to minutes as in conventional systems, the intermetallic thickness is less than a micron (compared to 5 mm in conventional processes). Thin intermetallic and complete independence from human variables improve solder joint quality — one key rework concern.

SMT

REFERENCE

1Schlieper, Fred, “Integration of X-ray Inspection and Rework Improves SMT Yields,” SMT Magazine, May 2001, p. 60-64.

RAY P. PRASAD is an SMT Editorial Advisory Board member and author of the textbook Surface Mount Technology: Principles and Practice. Additionally, he is president of BeamWorks Inc., a supplier of automated mass rework and selective assembly systems, located in Portland, OR, and founder of the Ray Prasad Consultancy Group, which specializes in helping companies establish strong internal SMT infrastructure. Contact him E-mail: smtsolver@rayprasad.com; Web site: www.rayprasad.com.

In an ideal world there would be no rework. Welcome to the real world. We have been doing through-hole assembly since the mid-1950s. We don’t have zero-defect in through-hole assemblies yet. We will never have zero-defect in any assembly — through-hole or SMT — as long as we need humans to do things.

Whatever the reasons, less than 10 percent of companies have first pass yields of more than 90 percent. To put it differently, 90 percent of companies perform excessive rework. What are the reasons for such poor performance? There are three major causes of defects: design for manufacturing (DFM), quality of incoming materials (i.e., adhesive, solder paste, boards and components) and in-house SMT infrastructure (i.e., equipment set up, thermal profile, documentation and training) at all levels in the organization. Training is very important. Nobody gets up in the morning and says, “I am going to screw up three things at work today.”

With the major trend toward outsourcing today, the contract manufacturer (CM) controls less than two thirds of defect causes because, in most cases, the OEM designs the board and is responsible for DFM. Typically even then, the OEM tells the CM who his suppliers are for the component and boards. If the CM is working on a consignment basis, in which all parts and boards are supplied by the OEM, he has control only over one third of the causes of defects. So while the CM generally has no or very little control over DFM and the quality of incoming material, he bears 100 percent responsibility (blame, actually) for the defects. I think we all can agree that rework is never going to go away. We can minimize it but we cannot eliminate it. It is important to reconcile with this reality so that resources can be put in place to address it. Most people probably agree that we have to deal with rework. But mass rework? That is another matter entirely.

Why Mass Rework?

I have been in the SMT industry for some time. I have yet to visit a company where mass rework has not been needed. The fortunate thing is that it happens only occasionally. When it does happen, however, it is a major crisis. For example, say 36 components (same component) have to be replaced on each board and you have to rework 5,000 boards. How and why do such things happen? Very simply, it could be that a wrong reel with a different part number was placed with the same types and number of leads. But what is the excuse for building such large quantity assemblies?

One reason the SMT process is so pervasive is that it is very high-speed and, hence, is natural for automation. But also keep in mind that if anything, no matter how trivial, goes wrong it takes almost no time to build thousands of assemblies that must be scrapped before the problem is discovered. If this has not happened to you, you are in denial, extremely lucky or have achieved nirvana.

If you do deal with high-volume rework, you are in big trouble with existing technology because it takes from 12 to 60 minutes to remove and replace one component. That is only one to five components per hour. For 100,000 components, assuming 12 minutes per component, that is 10 years! This is when you need an automated rework system.

Integrating Automated Inspection and Rework

In the May 2001 issue, there is an article by Fred Schlieper1 discussing benefits of integrating inspection and rework. While this article focuses on integrating X-ray and rework systems, the concept is equally valid for integrating automated optical inspection (AOI) with automated rework systems. The inspection system finds the problems and the rework system fixes them automatically. This creates an interesting opportunity for both the suppliers of these machines and the end customer. With the integrated system, problems are fixed with gathered data and corrective action is implemented to prevent future repetition.

There is one minor problem with automated rework systems. Does such a system exist? Before I answer this question, let us agree on the definition of automated rework systems.

In a fully automated rework system, all rework process steps — defective part removal, solder paste or flux application, vision-assisted precision placement of small and large components from tape-and-reel feeders or trays, and reflow without overheating the part being removed or reflowing neighboring components — must be accomplished automatically, without human intervention. And it also is helpful if the board does not warp because of intense local heating. A tall order, indeed. Does such a system exit?

Automated Rework Systems

There are many rework systems on the market today. They vary in cost from a few hundred dollars to $160,000. These systems are either manual or semiautomated. When I say semiautomated, I basically mean component placement either is totally manual or the operator gets some help in aligning the part for placement. And solder paste dispensing or printing is done manually with a syringe or ministencil. A ministencil is needed for each part type.

To fully automate rework, not a single machine but an assembly system that can selectively dispense solder paste, place components and reflow components without heating neighboring components is needed. The system also needs to be fairly fast to assemble quickly and automatically to meet the mass rework requirements. To provide a real relief, it must be able to selectively assemble many part types without the problem (and the cost that can add up quickly) of changing nozzles and stencils for each part type. There is only one system on the market (at least for now) that can perform all the functions of rework — Spark 400R from BeamWorks.

Before I briefly describe this machine, let me make a public disclosure to avoid any conflict of interest. I have significant interest in BeamWorks. I have been working with BeamWorks since its inception about three years ago and currently I play a major role in its operation. I also am an investor in this company.

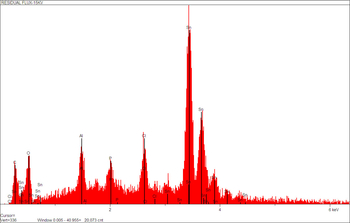

Spark 400R from BeamWorks is as an automated rework system. It performs all the functions of a rework operation — component removal, solder paste dispensing, component placement and laser soldering. Soldering and inspection functions are performed concurrently to provide real-time feedback on solder joint quality. It tailors heat input not only to a specific component but also to a specific lead. In other words, if a certain lead of a given component is connected to power or ground plane, the laser soldering time is longer for that lead than the adjacent lead that is not connected to any heat sink. Think of it as an assembly system that uses a unique solder profile not for a board but rather an individual lead.

Because the machine dispenses paste (or flux as is generally the case because enough solder is left on the pad after component removal), there is no need to spend money on ministencils for each component. Paste or flux dispensing, as the case may be, is done either as dots or a thin strip of paste or flux. Then, using the same computer-aided design (CAD) data, the system places components and solders them using four diode lasers. An important benefit is that the laser does not reflow solder joints of adjacent components even if they are only 0.020" away and does not need any nozzles. Because the board is not heated (only the solder pads are), board warpage is a non-issue. Also, because the heat source for reflow is a diode laser, the moisture-sensitive components already assembled (or to be assembled) do not require baking. This is very important when you want to selectively assemble only certain components.

Having such a system makes rework not the dreaded operation it is thought to be. Because all operations are performed without human intervention, quality is consistent. Because reflow time is in milliseconds as opposed to minutes as in conventional systems, the intermetallic thickness is less than a micron (compared to 5 mm in conventional processes). Thin intermetallic and complete independence from human variables improve solder joint quality — one key rework concern.

SMT

REFERENCE

1Schlieper, Fred, “Integration of X-ray Inspection and Rework Improves SMT Yields,” SMT Magazine, May 2001, p. 60-64.

RAY P. PRASAD is an SMT Editorial Advisory Board member and author of the textbook Surface Mount Technology: Principles and Practice. Additionally, he is president of BeamWorks Inc., a supplier of automated mass rework and selective assembly systems, located in Portland, OR, and founder of the Ray Prasad Consultancy Group, which specializes in helping companies establish strong internal SMT infrastructure. Contact him E-mail: smtsolver@rayprasad.com; Web site: www.rayprasad.com.

Registration is Open for SMT Course

Registration is Open for SMT Course

Ray Prasad will be teaching his flagship SMT course: