Lead Free-RoHS Implementation: Problems & Promises

To edit content for this class, please view items in this category.

- About the Lead Free-RoHS Course

- Understand the current status and driving forces for RoHS & lead-free conversion

- Understand how to do a detailed RoHS compliance audit of a supplier or be ready for RoHS audit by a customer

- Understand complex technical, cost and business issues in RoHS & lead-free implementation

- Understand the pros and cons of various laminate materials and surface finishes for lead free products.

- Understand metallurgy of lead free solder to enable selection of appropriate lead free surfaces finishes, solder alloys, soldering and rework processes and equipment

- Understand how to implement RoHS & lead-free technology in your products and manufacturing processes either in-house or at a subcontractor including dealing with the technical challenges of mixed technologies

- Conversion to Lead Free - Market Forces and Legislation

- Metallurgy and Selection of Lead-free Solders

- Designing For Lead Free Assembly

- Incremental Impact of LF Solder on PCBA Assembly Processes

- Technical Challenges of Mixed Assembly

- Market Forces Driving Lead Free and its impact on Electronics Industry

- RoHS Compliance

- RoHS Audit Process

- Sample Questionnaire for Supplier Selection and Qualification

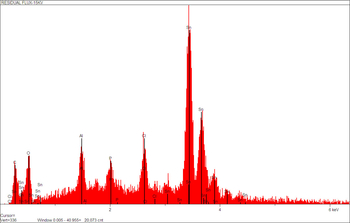

- Metallurgy of Lead-free Solders including low temperature solders

- Reliability of LF Solder Joints

- Various Types of Voids

- Tin Whiskers

- Component Considerations

- Laminate Considerations

- Surface Finish Considerations

- Printing

- Reflow

- Wave

- Selective Soldering

- Laser and Vapor Phase Soldering

- Rework and ICT

- Avoiding Component Mixing

- Avoiding board mixing

- Mixed Technologies

- Forward and Backward Compatibility

- Potential Mixed Technology Failure Modes

- Mixed Alloy BGA Solder Joints

- Reliability of Mixed Alloy Solder Joints

- Reflow Profile Windows for Mixed Alloy Soldering

- Gradual Transition to Pb-fee Assembly

- Advance your understanding of complex technical, cost and business issues in lead-free implementation including its benefits and pitfalls.

- Get an understanding of the current status of lead-free legislation worldwide

- Walk away with practical ideas to help you implement lead-free technology in your products and manufacturing process.

- Select appropriate lead-free SMT components, materials, processes, and equipment

- Explain how lead-free soldering affects cost, quality and reliability.

- 1A Market Forces Driving Lead Free and its impact on Electronics Industry

- RoHS Compliance

- RoHS Audit Process

- Sample Questionnaire for Supplier Selection and Qualification

- Metallurgy of Lead-free Solders including low temperature solders

- Reliability of LF Solder Joints

- Various Types of Voids

- Tin Whiskers

- Component Considerations

- Laminate Considerations

- Surface Finish Considerations

- Printing

- Reflow

- Wave

- Selective Soldering

- Laser and Vapor Phase Soldering

- Rework and ICT

- Preventing Pb Contamination

- Line Dedication

- Avoiding Component Mixing

- Avoiding board mixing

- Mixed Technologies

- Forward and Backward Compatibility

- Potential Mixed Technology Failure Modes

- Mixed Alloy BGA Solder Joints

- Reliability of Mixed Alloy Solder Joints

- Reflow Profile Windows for Mixed Alloy Soldering

- Gradual Transition to Pb-fee Assembly

THIS RoHS COURSE DESCRIBED BELOW, HAS BEEN MERGED INTO SMT-BGA-BTC COURSE SINCE MAJORITY OF THE COMPANIES HAVE MADE THE CONVERSION TO LEAD FREE.

THOSE COMPANIES WHO ARE STILL USING TIN-LEAD (e.g. Military), YOU STILL NEED TO DEAL WITH LEAD FREE COMPONENTS ESPECIALLY BGAs.

THE SMT-BGA-BTC COURSE ALSO DEALS WITH ALL THE TECHNICAL ISSUES RELATED TO DESIGN AND ASSEMBLY OF MIXED ASSEMBLY, ALSO KNOWN AS BACKWARD COMPATIBILITY WHERE LEAD FREE COMPONENTS ESPECIALLY LEAD FREE BGAs ARE SOLDERED WITH TIN-LEAD SOLDER PASTE.

IF YOU THINKING OF CONVERTING FROM YOUR CURRENT PROCESS OF TIN LEAD TO LEAD FREE, THIS RoHS COURSE DESCRIBED BELOW CAN BE OFFERED AT YOUR SITE. IN ADDITION, WE CAN TOTALLY CUSTOMIZE THIS COURSE TO MEET YOUR SPECIFIC NEEDS. YOU CAN USE THE DESCRIPTION BELOW (A TWO DAY COURSE) AND ALSO THE COURSE DESCRIPTION OF SMT-BGA-BTC COURSE TAUGHT IN BEAVERTON (OR YOU SITE) AND DEVELOP YOUR OWN COURSE OUTLINE. WE CAN WORK WITH YOU TO DEVELOP A CUSTOMIZED COURSE OUTLINE FOR ONE TO FIVE DAY COURSE.

HERE IS THE COURSE DESCRIPTION OF RoHS COURSE:

Is lead free also on your mind? It should be even if your industry may be temporarily exempt. Lead free impacts almost everyone in the electronics industry - from supplier of component, board and materials like paste and flux to manufacturers and users of electronics products and equipment including military and medical industry.

This is not a theoretical course. We will also show you how you can resolve the business and technical issues (principles as well as practice) for an effective implementation of lead-free at lower cost and higher yield.

Most lead-free solders have higher melting points than currently used tin-lead solders and thus pose a challenge for all board assembly processes, including rework. We will also cover use of low temperature lead free solders that address some of the technical issues in high temperature lead free alloys. They are becoming popular in many applications. As opposed to one tin-lead composition we have been used to, in lead free you may have to deal with multiple lead free BGA ball compositions with different melting points on the same board.

We will discuss the details of RoHS and WEEE legislation including the status of exemptions for various industries. In addition to discussing the details of in-house lead free implementation, we will also discuss technical issues when dealing with Contract Manufacturers.

We will provide you all the technical details including wave and reflow profile development, paste selection, inspection and rework using both conventional and laser. We will also provide you the status of legislation banning lead around the world including Europe, Japan, China and USA and how you can improve your company’s profile and benefit from this disruptive technology.

Objectives of this Course:

Brief Outline of the Course

Detailed Outline of the Course

Conversion to Lead-free- Market Forces & Legislation

Metallurgy and Selection of Lead-free Solders

Designing for Lead Free Assembly

IncrementalImpact of LF Solder on PCBA Assembly Processes

Technical Challenges of Mixed Assembly

Course Benefits

You will get an insight into the essential details of lead-free technology even if you think you may be exempt for a while. You can use the knowledge from this course to successfully implement lead-free in your process and products, and leverage your considerable investments to succeed in the marketplace. This information that you will gain will enable you to achieve higher yield, lower cost and faster time to market. After completing this course you will be able to:

AS NOTED IN COURSE DESCRIPTION, THIS COURSE HAS BEEN MERGED WITH THE SMT-BGA-BTC COURSE.

Course FeesAS NOTED IN COURSE DESCRIPTION, THIS COURSE HAS BEEN MERGED WITH THE SMT-BGA-BTC COURSE.

How to RegisterPlease register on the form below or contact Ray Prasad at Phone: 503-332-3215

Send your check to:

Ray Prasad Consultancy Group

12945 SW Glen Oak Place

Beaverton, Oregon, 97007

There are many hotels near the class location. The prices listed below are not negotiated rates and may not be valid for the days of your stay. Please call the hotel to confirm availability and rates.

America's Best Inn and Suites

3333 SW 198 th Ave

Aloha, OR 97006

503-642-4531

Larkspur Landing

3133 NE Shute Road

Hillsboro, OR 97124

877-310-5723

Courtyard PDX Hillsboro-owned by Marriott

3050 NW Stucki Place

Hillsboro, OR 97124

503-690-1800

Residence Inn-owned by Marriott

18855 NW Tanasbourne Drive

Hillsboro,OR97124

503-531-3200

Double treebyHilton-$152

15402NWCornellRoad

Beaverton,OR97006

503-614-8100

ExtendedStayAmerica-$130-queen/$140-king

19311NWCornellRoad

BeavertonOR97124

503.439.0706

Extended Stay America

18665NWEiderCrt

BeavertonOR97006

503.439.1515

Who Should AttendThe target audience for this course are Managers, Quality, Design and Process Engineers who would like to understand the essential details of lead-free soldering technology in order to successfully implement lead free and leverage their considerable investments to succeed in the marketplace. The knowledge gained from this course will enable you to achieve higher yield, lower cost and faster time to market with lead free products using circuits boards with through hole, SMT, fine pitch, BGA, CSP and MLF components.

Course OutlineAS NOTED IN COURSE DESCRIPTION, THIS COURSE HAS BEEN MERGED WITH THE SMT-BGA-BTC COURSE.

THE COURSE OUTLINE DESCRIBED BELOW IS INTENDED TO HELP YOU MERGE THE OUTLINE DESCRIBED BELOW TO MERGE WITH THE OUTLINE DESCRIED UNDER SMT-BGA-BTC COURSE TO HELP YOU DEVELOP YOUR OWN CUSTOMIZED COURSE OUTLINE IF YOU DESIRE TO HAVE US TEACH THE COURSE AT YOUR SITE.

Detailed Outline of the Course

Conversion to Lead-free- Market Forces & Legislation

Metallurgy and Selection of Lead-free Solders

Designing for Lead Free Assembly

IncrementalImpact of LF Solder on PCBA Assembly Processes

Technical Challenges of Mixed Assembly

Registration is Open for SMT Course

Registration is Open for SMT Course

Ray Prasad will be teaching his flagship SMT course: